UL electronic yellow glue refers to the electronic glue with flame retardant effect after glue curing, because of the color of the glue is yellow, so the industry has been called UL glue or UL yellow glue, UL flame retardant yellow glue, electronic yellow glue and other names.

The main material of UL flame retardant yellow glue is neoprene rubber. In addition, it is a single component glue composed of flame retardant materials and environmental protection solvents. It belongs to the solvent volatile bonding glue.After curing, the product has excellent flame retardant performance, which can reach UL94V0 flame retardant grade. It has the characteristics of insulation, fixing, positioning, reinforcement, earthquake resistance, moistureproof, strong adhesion and so on, and has good toughness.The following will introduce the details of Yoneng flame-retardant electronic yellow glue 1603 model products.

I. [Product Features]

1. It is a kind of one-component adhesive composed of environmental protection resin, flame retardant material, rubber environmental protection solvent, etc. It is simple and convenient to operate, short positioning time, and high initial adhesive strength.

2. After curing, the product has excellent flame retardant performance, insulation, earthquake resistance, moistureproof, strong bonding force and good toughness.

3. It can bond, paste and position electronic products;Good adhesion to plastics, wire, wood, glass, metal, leather, rubber, electronic parts, electronic components, circuit boards, semiconductor devices, ceramics.

Two, [scope of application]

Yoneng 1603 electronic flame retardant yellow glue is suitable for the following products and range:

1, can be widely used in audio-visual appliances, TV, monitor, audio and other household appliances in the loose parts fixed.Bonding, positioning, filling, sealing, insulating and fixing of electronic industrial components, PCB circuit boards, wire coils and other components.Including hard to stick materials such as rubber, plastics, ceramics and so on.

2, widely used in metal, glass, ceramics, PCB, semiconductor devices, plastic and other objects bonding, sealing, fixing.

III. [Technical Indicators]

|

Name of index |

Condition/Unit |

Index value |

|

|

Before solidify |

Name/Model |

/ |

Flame retardant cement 1603 |

|

Brand/Origin |

/ |

Yaoneng/Guangdong |

|

|

Appearance |

Visual inspection |

Yellow half flow |

|

|

Viscosity |

25℃/mpa.s |

4500 |

|

|

Density |

25℃,g/cm3 |

1.2 |

|

|

Surface drying time |

25℃/min |

1~3 |

|

|

Full drying time |

25℃/h |

24-48 |

|

|

After solidify |

Solidify appearance |

/ |

Yellow hard colloid |

|

Hardness |

shore D |

45-55 |

|

|

Flame resistance |

UL94 |

V0 |

|

|

Operation temperature |

℃ |

-40-130 |

|

|

Shear strength |

N/cm2 |

130 |

|

|

Permittivity |

60Hz |

3.0 |

|

|

Volume resistivity |

Ω.㎝ |

2.0×1013 |

|

|

Dielectric dissipation factor |

60Hz |

0.003 |

|

|

Breakdown voltage |

Kv/mm |

20-25 |

|

▲Above mechanical and electrical properties of products were measured 72 hours after complete curing at 25℃ and relative temperature 55%.

IV. [Usage]

1, clean: clean the surface of the construction substrate dust, water, oil and other impurities, and keep dry.

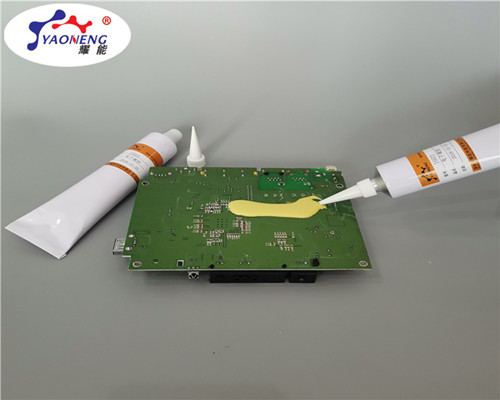

2, sizing: can be directly squeezed on the construction parts (3kg/ barrel packaging, can first pour the glue into the nozzle plastic bottle, or directly pour the glue into the plastic bottle with the glue dispenser dispensing), then the components are bonded and fixed.25℃ for 2-3 hours positioning (can enter the next process), 24 hours after the maximum strength (according to the size of the area, temperature and other factors, curing time will change).

5. [Precautions]

1. Venting and personal protection should be strengthened in the production process. Open fire is strictly prohibited and fire sources and heat sources should be kept away.

2, handling light, packaging cover should be promptly covered, not used up glue should be sealed, so as not to glue thickening.

3, the test of various performance parameters should be carried out at least 72 hours after sizing, at this time the glue is completely cured.

4. For more data and information, please consult Shenzhen Yaoneng Company for relevant advice and help.

More electronic cement, UL flame retardant cement, cement, UL white glue, electrical insulation strength cement, plastic screws, screws, screw glue, glue, red glue, electronic green solvent adhesive, electronic vinyl products related information to or visit yaoneng can company consultancy company website, we will wholeheartedly for your service,We can provide free sample testing, small batch trial production testing and related technical support for our customers.

Contact: MR, SUN

Phone: 139-2653-4463

Tel: 0755-27902799

Email: ynbond@126.com

Add: SHENZHEN GUANGDONG CHINA