I. [Product Features]

1, one component resin, low viscosity, low smell, can form a strong protective film, good insulation performance

2, fast drying insulating paint, strong adhesion, wear resistance, acid and alkali resistance, oil resistance, tough and durable

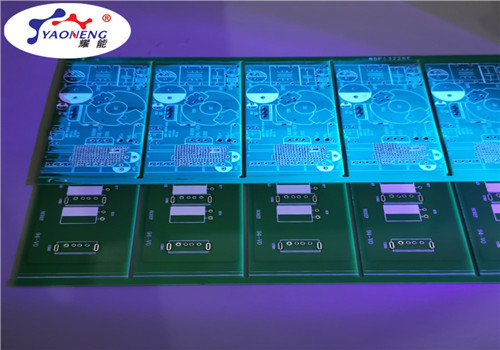

3, high and low temperature resistance, good chemical resistance;Curing at room temperature, with fluorescent agent, easy to detect

Two, [Scope of application]

Yaoneng 162 three anti paint is suitable for all kinds of assembled PCBA circuit board, protect circuit board from various chemicals, moisture, salt spray corrosion, dust and high and low temperature and other harsh environmental impact, prolong the service life of equipment and improve the safety and stability of products.After curing, the film is dense and bright, with strong adhesion and good appearance.At the same time has superior insulation, moisture, leakage, shock, pollution, dust, mildew, salt spray, corrosion, corona resistance, oxidation resistance and other characteristics, can play a significant multi-prevention effect.It is mainly used in hybrid integrated circuit, automotive electronic control board, electronic circuit board, aviation instrument panel, soft printed circuit, microcomputer control board, semiconductor crystal circuit board, home appliance control system, etc.

Three, [Technical indicators]

|

Name of index |

Condition/Unit |

Index value |

|

|

Before solidify |

Name/Model |

/ |

Conformal coating 162 |

|

Brand/Origin |

/ |

Yaoneng/Guangdong |

|

|

Appearance |

Visual inspection |

yellowish transparent liquid |

|

|

Viscosity |

25℃/mpa.s |

260 |

|

|

Density |

25℃,g/cm3 |

0.95 |

|

|

Solid content |

% |

45~50 |

|

|

Surface drying time |

25℃/min |

10~15 |

|

|

Full drying time |

25℃/min |

60(80℃30Min) |

|

|

After solidify |

Glossiness |

/ |

Bright |

|

Hardness |

shore D |

60 |

|

|

Breakdown voltage |

KV/mm |

60 |

|

|

Permittivity |

1MHz |

5.4 |

|

|

Volume resistivity |

Ω.㎝ |

7.8×1011 |

|

|

Dielectric loss |

1MHz |

0.01 |

|

|

Operation temperature |

℃ |

-40~130 |

|

|

Waterproof class |

/ |

IP65 |

|

|

Heat-resisting class |

/ |

Class B |

|

|

Maintainability |

/ |

yes |

|

Iv. [Method of use]

1, clean and dry circuit board.Before use, clean or clean the circuit board surface dust, impurities, oil, and remove moisture and moisture.It is recommended that 60℃ drying board for 10 to 15 minutes, the circuit board in the oven after natural cooling can be taken out and coated with three-proof paint.

2, cover and shielding.Some areas and parts of the circuit board are not allowed to be covered with tri-proof paint, such as switches, sockets, connectors, radiators, etc.Yao neng company recommends the use of tape or other tools for protection before construction.

3, the use of technology.A, spraying process: spraying construction of the mixed three-proof paint directly into the spray gun can, the air pressure of the spray gun, spray nozzle and paint flow can be adjusted, sealed directly for spraying use.Three anti paint consistency is too large can be added yaoneng 120 model special thinner for use, stirring evenly should be left for 10 minutes, to remove the bubble before construction, three anti paint and diluent ratio does not exceed 1.5 times.B, brush painting process: according to the size of the product, the wool brush is correctly selected, the glue is poured into the container, and then the brush is adhered to the appropriate glue for uniform construction of the circuit board, according to the required thickness of The Times of brushing.After gluing is finished, the surface can be assembled or packaged after curing. If the first paint needs to be dried for two times, the first paint should be painted again.C. Immersion process: Immerse the immersion part in the glue solution for 2-5 seconds, slowly lift the immersion part and tilt it until the excess glue liquid naturally flows off. Lay the immersion part flat on the absorbent paper (small pieces) or support (large pieces). Generally, the surface will dry within 10 minutes, check the surface of the immersion part, and brush the areas not painted with repaint.

4. Fix the problem.To repair the circuit board that has been completed, simply heat the area with a soldering iron to remove the coating, then repair and replace the relevant parts, and then clean and dry the surface of the board, and then brush the paint.If the three-proof paint coating is soft, it can be removed with plastic scraper.

V. [Matters needing attention]

1, three anti paint in use, the construction site humidity can not be greater than 85%, otherwise there will be slightly white moisture absorption phenomenon.

2. In the production process, ventilation and personal protection should be strengthened. Open fire is strictly prohibited, and fire and heat sources should be kept away.

3, when handling light, light, packaging cover should be covered in time, used brush, spray gun, etc. should be cleaned in time for the next time.

4. The test parameters should be carried out at least 24 hours after painting, when the relevant values reach the maximum and stable values.

5, three anti paint will generally have odor, but three anti paint is completely cured after no odor.

6. For more relevant data and information, please consult Shenzhen Yaoneng Company for relevant advice and help.

Contact: MR, SUN

Phone: 139-2653-4463

Tel: 0755-27902799

Email: ynbond@126.com

Add: SHENZHEN GUANGDONG CHINA