Domestic conformal coating after at home for nearly 30 years of development and technology precipitation, part of domestic conformal coating production of the enterprises in the aspect of quality can reach or exceed import conformal coating completely related to quality, the quality excellent conformal coating has been selected customers include the world famous enterprises, to enter the global procurement system,Make the domestic three anti paint successful and imported three anti paint to enter the procurement objectives and product competition of multinational companies, break the foreign brand three anti paint in the product and technology monopoly position,Domestic conformal coating is widely used in electronic and electrical appliances, aerospace, information and communication, automotive electronics, electrical and electrical, electronic power, power equipment, instruments and meters, consumer electronics, household appliances, lighting, intelligent industrial control and other fields, has become an indispensable protection material for circuit board protection and electrical product safety.

So do domestic 3 prevent lacquer and import conformal coating the quality between them and other respects still have gap?Yoneng technology to do a relative comparison between them.

1, quality: domestic three anti-paint production in strict accordance with the mature formula and strict selection of raw materials, production before, during and after the production of strict quality detection and inspection.

2, certification: domestic three anti-paint are in line with the RoHS directive requirements, some products in line with UL certification standards.

3, shelf life: domestic three anti paint shelf life between 6 months to 18 months, the use of a wide range of time, fully reach the shelf life of imported three anti paint.

4, product performance: domestic three anti paint in high and low temperature resistance, adhesion and waterproof performance is excellent, the data reached the same value of imported products.

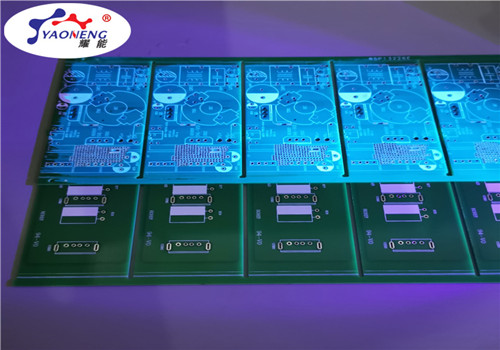

5, product categories: Yaoneng three anti paint categories are: acrylic three anti paint, silicone three anti paint, polyurethane three anti paint, UV three anti paint and other categories, basically covering all categories of three anti paint, a wide range of choices, can meet the needs of different fields and products for three anti paint.

6, packaging: because the three anti paint generally contains solvents, so the three anti paint is generally packaged with metal containers, packaging specifications are 1L, 5L, 20L, 18KG and other packaging specifications.

Above is yao neng domestic three anti paint and imported three anti paint products in quality and other aspects of the comparison, if you need to know more about my company three anti paint products detailed data and information, three anti paint sample demand, please contact with shenzhen yao neng company, will provide our customers with high value-added products and services.

Three anti coating, also known as circuit board three anti coating, three anti adhesive, insulating paint, coating glue, coating glue, moisture-proof oil, general film coating, coating coating, electronic coating materials, etc., is English name Conformal coating.Three anti paint is a single component of room temperature curing, heating curing, UV curing transparent or translucent adhesives, with low viscosity, high transparency, excellent insulation performance, high and low temperature resistance, easy to use and so on.Three anti paint is mainly applied to all kinds of assembled electronic circuit board surface coating, coating role, to provide protection for circuit board, so that circuit board to moisture-proof, anti-fouling, anti-salt spray, insulation and other anti protection, in order to improve the performance, safety, stability and service life of the product.

Contact: MR, SUN

Phone: 139-2653-4463

Tel: 0755-27902799

Email: ynbond@126.com

Add: SHENZHEN GUANGDONG CHINA